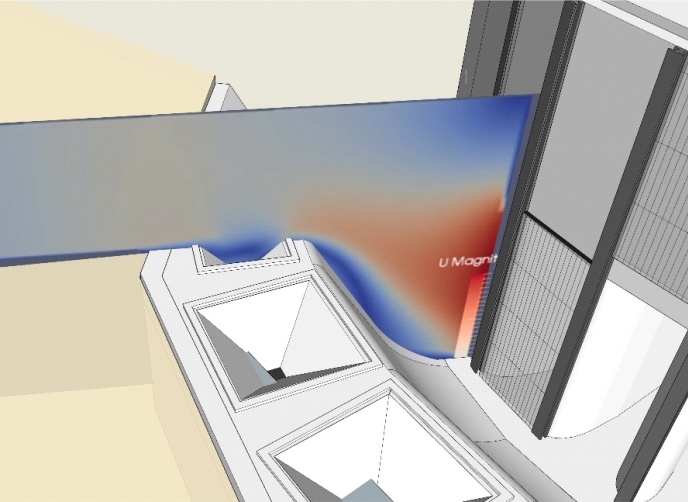

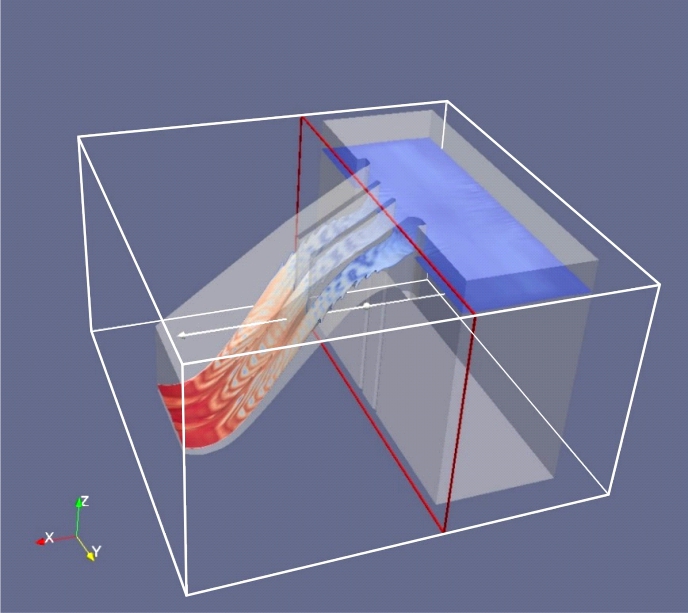

CFD

simulation of Spillways

Contribute to the generation of new knowledge in one of the most complex scientific/technical challenges in the design of hydroelectric power plants (HPP), the design of hydrodynamic structures such as spillway that allow for the safe and reliable discharge of flows.

In this sense, COBA’s R&D team aims, through the Computational Fluid Dynamics (CFD) method, to develop new numerical analysis models for the simulation and characterisation of the hydrodynamic behaviour of flow in spillways, taking into consideration the wide range of settings (geometrical, geotechnical, flow, water levels and sediment transport).

The R&D projects will also have multiple experimental applications that aim to enhance the numerical model, in order to make it applicable to various application contexts (e.g. different watershed layouts or flow typologies) and, as well as, to different hydropower developments.